DuraPlaq is privy to intricate designs, textured mediums and specialty media. Raised and textured print, white ink, sophisticated die-cuts, wraps and applications are a signature feature of our diverse substrates and display options. Utilizing cost-effective design methods to maximize efficiency and lower your costs, our direct-print, UV-coated printers offer ink layering and texturing that rivals dimensional reality!

Our pressroom includes Canon’s Oce Arizona UV Flatbed Printer, affording a fast, cost-effective solution for dimensional media. While most printers are only able to offer a maximum sheet size of 20” x 29”, our sheet sizes span 98” wide by 120” long and up to 2” thick.

Well-versed in producing projects that make you stand out, our textured ink solutions produce stunningly realistic textures that expand your design options to virtually limitless possibilities. DuraPlaq’s print production team are experts in printing on coated, uncoated, metallic, recycled, clings, specialty papers, paperboard and a vast array of unique substrates! The combination of textured inks with substrates with specialty inks like white ink, raised ink, and textured effects will create a hallmark presentation for your commercial or residential application!

To view samples and discuss textured ink applications for your next project, contact DuraPlaq’s design team today at (970) 341.3821 or email us at plaqit@duraplaq.com.

Please contact our customer service team at +1 970.381.3421 or email us at orders@duraplaq.com if you have any questions, comments or concerns when placing your order.

Prepping Your Files For Printing

For the best resolution and end product, please submit image files in 8 or 16 bit format using Adobe 98. For optimal print resolution, files should maintain 300 or 600 dpi at the desired print size, in tiff, jpeg, psd, or psb format. Please make sure your artwork reflects the required image file dimensions for our preset dimension products.

Custom Size, Custom Price

Customization is our standard, so there is no need to compromise or crop the native dimensions of your image. All products are produced using the dimensions that you specify (rounded to the nearest 1/8″). Please refer to our PRICING tab for preset pricing and customization option

If you need to display a custom print or presentation style, please feel free to contact our team to discuss your design needs!

Manufacturing Margins

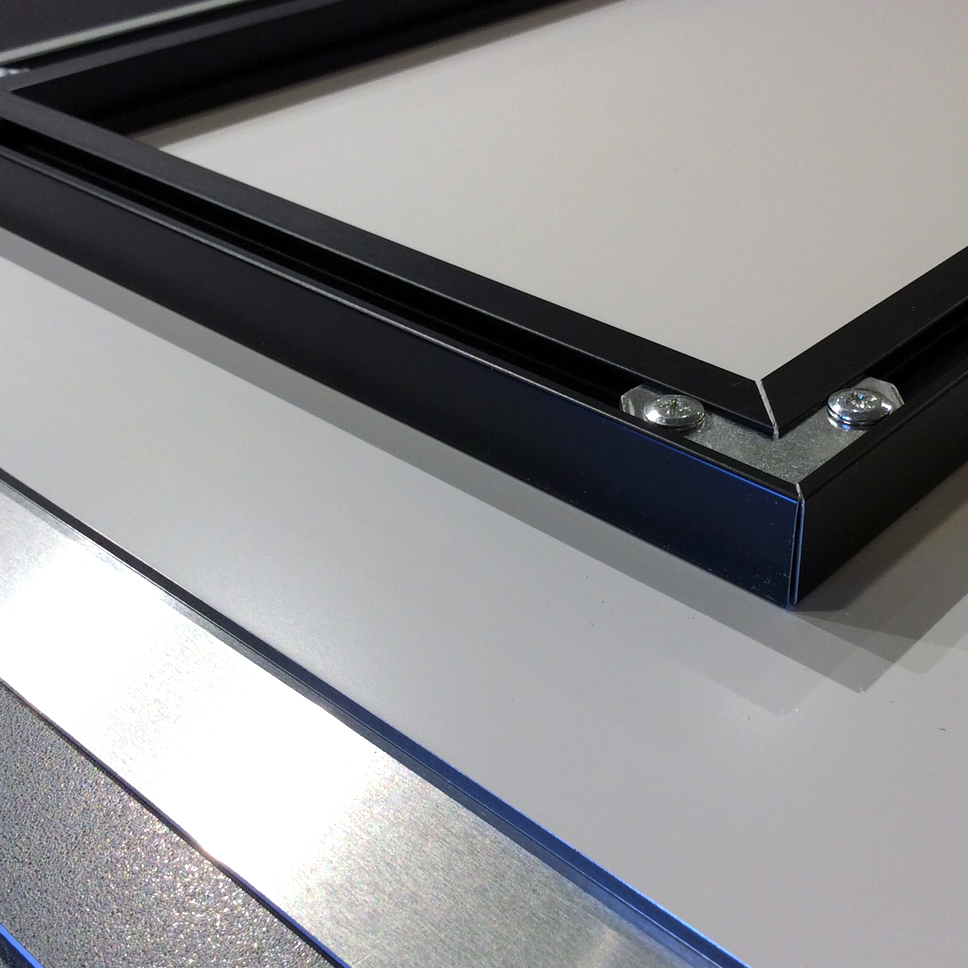

Artwork that is subject to beveled edging can reduce your artwork dimensions up to 1/4″ from each side. Placement of your signature or crucial image composition should placed at a minimum of 1/4″ away from this trim margin. Please review our Terms and Conditions for additional details regarding image resolution, customization, applicable fees and more.

Due to the nature of printing to materials with varying base colors, textures and finishes, there may be variations in the surface and overall appearance of a direct or infused print. Inks and end product quality are not guaranteed with customer provided materials due to varying ink transfer and adherence of materials. We do not offer replacements on customer provided materials or prints if end product does not meet customer expectations.

Every DuraPlaq product is developed and designed with durability and ease of care as one of our core objectives. Our products are delivered with the highest quality standards in preservation and protection, tailored to illuminate your artwork’s color and luster throughout its life cycle.

DuraPlaq products are primarily designed for indoor use, ideal in low to moderate humidity. To maintain your product’s longevity, it is not recommended to display artwork in prolonged, direct sunlight, or store in environments over 150 degrees Fahrenheit.

Ammonia-free glass cleaner and a clean cloth are recommended for the general cleaning of a DuraPlaq products.

For best results, … spray glass cleaner on a clean, soft cloth (prevent over-spraying and streaking on the surface), and wipe-down a plaque with gentle, circular motions. Many surface finishes will allow for heavier grease or debris removal using additional cleaning products (noted below); varying per surface finish.

Please do not use ammonia or acetone-based cleaning products. These chemicals dramatically reduce the longevity and durability of our protective finishes.

SURFACE FINISHES

SURFACE FINISHES

DuraPlaq surface finishes protect and preserve artwork with a durable, UV-protective and water resistant finishes.

SATIN FINISH:

Satin Finish is DuraPlaq highest gloss finish. Products that feature our Satin Surface Finish includes a complimentary Novus® Fine Scratch Remover and Novus® Plastic Clean & Shine packs. These products (found in your hardware pillow pack) can be used to buff-out hairline scratches. DuraPlaq applies Novus® polishes to our Satin surface finishes before packaging the finished piece.

Satin Finish yields a moisture-resistant and UV-protected finish; it can be used indoors even in high humidity environments. Even with the durable and UV protective satin finish, it is not recommend to hang artwork in prolonged direct sunlight or leave in heat over 150 degrees Fahrenheit.

VELVET FINISH:

Velvet Finish is DuraPlaq’s most durable surface coating. This finish has a slight texture that protects from scratches and other damage. As a high durability finish, it is most popular in high traffic and commercial environments.

To clean Velvet Finish, we recommend using ammonia-free glass cleaner in conjunction with a clean cotton or micro fiber cloth. Velvet Finish is a moisture-resistant and UV-protected finish and can be used indoors–even in high humidity environments. Even with UV protection we don’t recommend hanging artwork in prolonged direct sunlight. Please do not leave this surface finish in prolonged heat over 150 degrees Fahrenheit.

To remove heavier grease (fingerprints) or debris, Isopropyl or Denatured Alcohol may be used for cleaning.

MATTE AND SEMI MATTE FINISH:

Matte and Semi-Matte Finishes can be cleaned with ammonia free glass cleaner and a clean cotton or micro fiber cloth. You may also us Isopropyl or Denatured Alcohol to remove heaver grease or debris. These are moisture resistant and UV protected finishes. It can be used indoors even in high humidity environments. Even with UV protection we don’t recommend hanging artwork in prolonged direct sunlight. Please do not leave this surface finish in prolonged heat over 150 degrees Fahrenheit.

ECONOMY LINE PRODUCTS AND DIRECT PRINTS:

Direct prints have a UV and water-resistant protection integrated within the ink, eliminating the need for added surface protection upon application. These prints are resilient to UV light and can be used in strenuous environmental conditions, such as direct sunlight–even usage in the seasonal outdoors.

Please note that during cleaning some residual ink may show on the cloth during the first couple cleans. DuraPlaq does not recommend the use of denatured alcohol or acetone in the cleaning of these products.

FRAMES:

Frames come in many different varieties and finishes. DuraPlaq recommends using only ammonia free glass cleaner and micro fiber or cotton cloths to clean these products. Water and moisture should be removed immediately as most frames are constructed of wood, which can be adversely affected by prolonged exposure to moisture.

GLASS:

DuraPlaq glass products are best cleaned with an ammonia free glass cleaner and micro fiber or cotton cloths. Spraying on the cloth will prevent over spraying. Using round circular motions work well to prevent streaks. If the glass you purchased is UV protected it can be used in UV light areas. Even with UV protection we don’t recommend hanging artwork in prolonged direct sunlight.

PLEXI PRODUCTS:

DuraPlaq Plexi products can be clean easily with an ammonia free glass cleaner and micro fiber or cotton cloths. Spraying on the cloth will prevent over spraying. Using round circular motions work well to prevent streaks. DuraPlaqs normal Plexi products are UV protected and have an added scratch protection on the surface. This prevents hairline scratches from occurring during cleaning. Even with UV protection we don’t recommend hanging artwork in prolonged direct sunlight. Please do not leave Plexi products in prolonged heat over 150 degrees Fahrenheit.